Fundamentals of Blade Coating Technology | Key Processes and Solutions for Common Problems in Laboratory Film Making

Release time:2025-04-25

In the laboratory, electrode coating often suffers from the following typical problems due to rudimentary equipment, raw material contamination, unstable coating process, non-standard operation, and drying environment:

1. Uneven coating: Insufficient parallelism between the doctor blade and the foil, resulting in a coating thickness deviation exceeding ±10%;

2. Thick edges: Uneven slurry fluidity or die lip wear, with the edge thickness 20%-30% higher than the center;

3. Bubbles and pinholes: Insufficient vacuum degassing time (<2 hours) or slurry storage exceeding 12 hours, leading to local agglomeration;

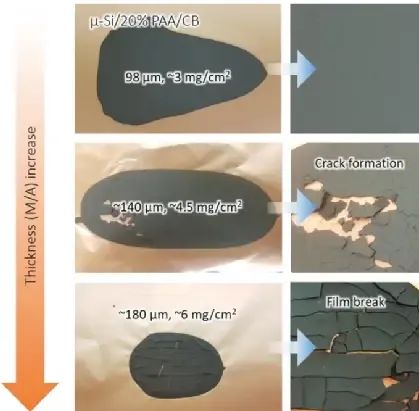

4. Drying cracks: Improper gradient temperature control, resulting in rapid surface curing while internal solvent remains;

5. Equipment malfunction: Unstable tension control of the manual coating machine, causing foil deviation or tearing.

Therefore, reducing coating defects, improving coating quality and yield rate, and reducing costs during the coating process are important aspects that need to be researched in coating technology.

(Image source: Internet)

A university laboratory experienced a 15% deviation in battery capacity testing due to uneven coating, requiring the electrodes to be remade. By introducing a small extrusion coating machine with closed-loop feedback, the thickness error was reduced from ±10% to ±2.5%, significantly improving the reliability of the experimental data.

01. Core Value of Coating

The core objective of electrode coating is to uniformly coat the active material slurry (such as lithium iron phosphate, ternary materials) onto the current collector (aluminum foil/copper foil), forming an electrode layer with a thickness of 100-300μm. This process directly determines the three major performances of the battery:

Energy density: For every 1% improvement in coating thickness uniformity, battery capacity can increase by 0.8%;

Cycle life: Thick edges lead to local stress concentration, accelerating capacity decay by 20% after 200 cycles;

Safety: Bubble defects may cause micro-short circuits, increasing the risk of thermal runaway by 3 times.

CATL uses a slit-die extrusion coating machine, with a double-sided coating speed of 100m/min and a surface density error ≤±1.0%, reducing the production cost per GWh by 15% and promoting the mass production of power batteries. (Data from CATL official website; third-party data is for reference only.)

(Image source: Internet, please delete if infringement)

02. Golden Operation of Laboratory Coating Process

'*Slurry Control'

Viscosity: Control within 2500-15000mPa・s; too low will cause sagging, too high will make coating difficult;

Solid content: 30%-40% is recommended in the laboratory; high solid content (>60%) requires a heated die.

'*Process Parameters'

Coating gap: Aluminum foil gap 100-150μm, copper foil 150-200μm, needs to be dynamically adjusted according to the slurry viscosity;

Drying temperature: Gradient temperature increase (e.g., 80℃→120℃→150℃), avoid "dry outside, wet inside";

Tension control: Aluminum foil tension ≤5N, copper foil ≤8N, to prevent foil deformation.

'*Defect Response'

Pinholes: Slurry storage time ≤12 hours, temperature < 35℃;

Thick edges: Regularly polish the die lip, add dispersants (such as PVP) to the slurry;

Bubbles: Vacuum degassing time ≥2 hours, coating speed ≤80m/min.

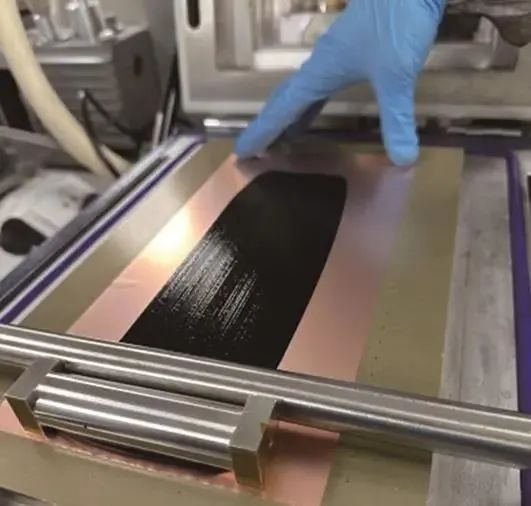

(Image source: Internet: Manual coating)

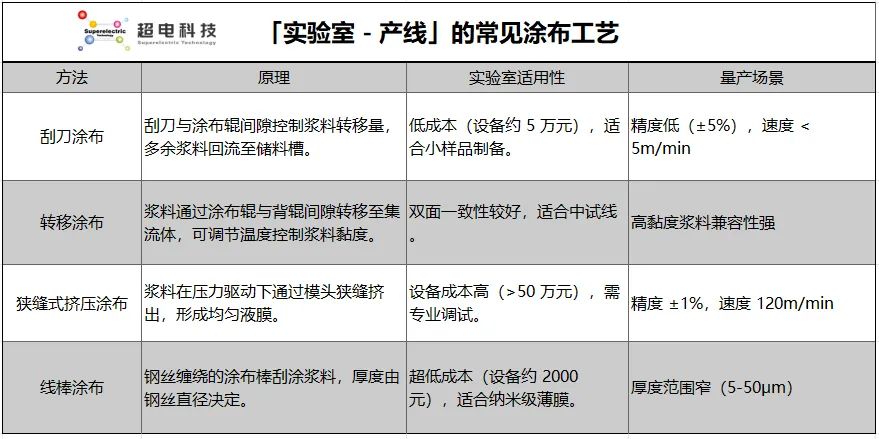

03. Coating Machine Selection

▶Laboratory scenarios:

Basic requirements: Choose a wire-bar coater or a small doctor blade coater, which is low-cost and easy to operate;

Advanced requirements: An automatic coating machine equipped with a heating platform and vacuum adsorption, supporting high-precision thin film preparation.

▶Pilot production scenarios:

Efficiency priority: Slit-die extrusion coating machine, double-sided coating speed 100m/min, surface density error ≤±1.0%;

Green manufacturing: Using heat recovery technology, energy consumption is reduced by 30%.

Laboratory Equipment Recommendation - Chaodian Coating Equipment

Automatic Coating Machine SPC-TM300

This product is widely used in various coating research, such as ceramic films, crystal films, battery material films, and special nanofilms. PLC touch screen control, various parameters are easy to set and observe; coating speed is adjustable in the range of 0~150mm/second; vacuum aluminum plate, substrates can be quickly placed or removed; adjustable stroke in the range of 0~300mm; with a micron-level adjustable coater (10μm scale), 100mm wide doctor blade; small size, saving space; sheet metal uses three-dimensional geometric design, simple and beautiful.

Automatic Coating Drying Machine SPC-ZTH300-P001

This product is suitable for high-temperature coating research on ceramics, crystals, battery materials, and nanofilms, meeting the film-forming needs of energy, catalysis, and electronic devices. Large-area heating technology ensures uniform temperature within the chamber, supporting precise temperature control from RT to 300℃ (high-temperature type optional). The motor-driven scraper allows stepless adjustment of coating speed. Combined with the standard film-making device, the thickness is flexibly controllable from 50-500μm. The aluminum tray can be quickly loaded and unloaded. With built-in/external vacuum sources, the substrate is adsorbed without deformation, adapting to flexible materials such as copper foil and aluminum foil. It can be embedded in a glove box, is small and space-saving, and features convenient parameter setting via a PLC touch screen.

Bottom Heating Coating Machine SPC-DRTM300

This product is widely used in various high-temperature coating research, such as ceramic films, crystal films, battery material films, and special nanofilms; it can adapt to the development of scientific technology for film formation under future high-temperature conditions. PLC and touch screen control make parameter setting and observation convenient; a micrometer-level scraper (accuracy 0.01mm) provides high precision; the coating speed is adjustable within the range of 0~120mm/second; the vacuum aluminum tray allows for quick placement or removal of substrates; and the range is set within 0~300mm on the touch screen.

Hotline: 027-8580 9599

Electrode coating is shifting from "experience-driven" to "data-driven," and laboratory results are crucial to the speed of energy technology development. The transition from "trial and error" to "data precision" necessitates attention to these three areas of capability building:

01. Equipment Upgrade

Does manual coating rely on operator feel? Try a small automated coating machine. Parameter setting and observation are convenient, with a micrometer-level scraper offering high precision and adjustable coating speeds from 0~120 mm/second. Experimental repeatability is significantly improved, eliminating concerns about "electrode preparation consistency" being questioned.

02. Process Standardization

After each experiment, record the slurry formulation (solid content/viscosity), equipment parameters (speed/temperature), and electrode data (thickness/defects) to build a "coating process database." For example, if it's found that "slurry storage exceeding 12 hours easily leads to pinholes" or "copper foil tension >8N leads to wrinkles," these risks can be avoided in subsequent experiments, increasing efficiency by 50%.

03. Technology Tracking

Pay attention to technologies such as water-based slurries (replacing NMP solvent, environmentally friendly and easy to operate) and three-dimensional gradient structures (reducing interfacial impedance and improving rate performance), and verify their feasibility in the laboratory in advance. These innovations can enhance research depth and add "process innovation" highlights to papers.

When equipment learns "intelligent control," data helps you "avoid pitfalls," and cutting-edge technology becomes a "bonus," experiments no longer rely on "feel" and "luck." The key to improving research efficiency lies in using data to drive every step of the operation, reserving energy for true innovation—this is the core competitiveness of modern laboratories.

Article content references the following contributions from researchers:

**《Research Progress on Lithium-ion Battery Electrode Coating Technology》Cao Wei, Chen Fei, Kong Xiangdong, et al. (《Energy Storage Science and Technology》2025, Issue 1)**

**《Slot Die Coating of Lithium-Ion Battery Electrodes: Investigations on Edge Effect Issues》Marcel Schmitt et al. (《Journal of Coatings Technology and Research》2014)**

**《Enhanced Cycling Performance of Silicon-Based Anodes by Double-Layer Coating》Unknown (《Advanced Energy Materials》2024)**

**《Three-Dimensional Gradient Electrodes Reduce Interfacial Impedance》Penghui Energy (《Journal of Power Sources》2025)**

**《2024-2030 Global Lithium Battery Electrode Coating Machine Market Report》QYResearch (Beijing Hengzhou Bozhi International Information Consulting Co., Ltd., 2024)**

**《Technological Innovation and Future Trends of Lithium Battery Electrode Coating Technology》Lithium Battery Research Institute (2025)**

**《Xinyuren Unidirectional Double-sided Coating (SDC) Technology White Paper》Xinyuren (2024)**

**《Weilingfesse Electrode Coating Heat Recovery Technology Practice》Weilingfesse (2025)**

**Contemporary Amperex Technology Co., Limited: Coating device and battery production line (CN 221869038 U)**

**Ganfeng Lithium: Double-layer coating process for electrodes (CN 119275220 A)**

**Amate: Coating slurry and its preparation method (CN 119662076 A)**

**Huitian New Materials: 1206L PAA negative electrode glue technology white paper**

**《Principles and Applications of Lithium-ion Battery Manufacturing Technology》Yang Shaobin, Liang Zheng (Chemical Industry Press, 2020)**

**《Lithium Battery Manufacturing: A Deep Dive into the Gigafactory》Christopher Iaco (Amazon, 2023)**

**《ECS Transactions: Lithium-Ion Battery Manufacturing》The Electrochemical Society (2024)**

Other content is collected from publicly available online resources.

Through the above literature, the basic theory, process optimization, equipment selection, and future trends of electrode coating can be systematically mastered, taking into account both laboratory research and industrialization needs.

✦ Chaodian Technology Interactive Topic

👉Is your laboratory coating manual or automated? What problems have you encountered during the coating process? Share your solutions in the comments.

✋Follow the backstage private message [Solid State] to receive the 《2025 China Solid-State Battery Technology Seminar Expert Report》.zip data package (big-name PPTs)

Extreme film coating process,Coater,Automatic coating machine,Battery Assembly,Automatic coating machine

Related News

Focus on us