What are the bottlenecks in the mass production of solid-state batteries? How can dry-film electrode technology overcome the two major challenges of coating cracks and solvent residue?

Release time:2025-06-10

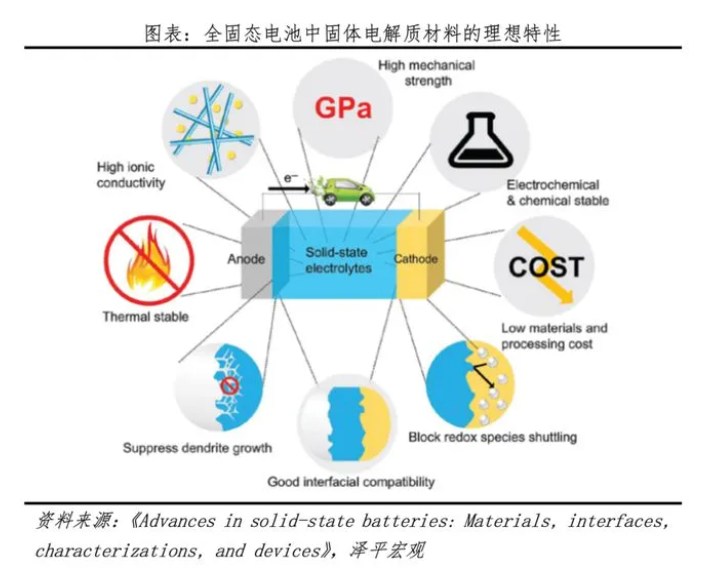

Solid-state battery materials are currently a core bottleneck hindering the commercialization of all-solid-state batteries due to issues such as high interfacial impedance, uneven electrolyte coverage, and difficulties in mass production. Currently, innovation in electrode manufacturing processes is the key to breaking through this bottleneck. Traditional wet processes face problems such as solvent residue and interfacial cracks in solid-state electrolyte coating, while dry processes are becoming the industry focus due to their solvent-free nature and high compatibility.

Image source network, delete if infringement

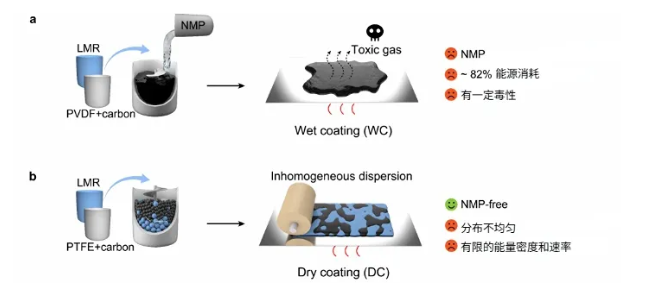

Comparison of technical paths between wet and dry processes

Wet process

Process characteristics: Using the slurry coating technology of liquid batteries, the solid-state electrolyte (such as oxides, sulfides) is mixed with the active material to form a slurry, which is coated and dried before being compounded with lithium metal.

Advantages: Compatible with existing production lines, good electrode uniformity, suitable for polymer electrolyte systems.

Bottlenecks:

Oxide electrolyte: High-temperature sintering (≤700℃) is required to improve interfacial density, but it is easy to cause grain boundary cracks, high energy consumption, and difficult to quantify control;

Sulfide electrolyte: Non-polar solvent (such as xylene) processing is complex, binder selection is limited (PVDF needs to be replaced), and delamination is easy after calendering;

Solvent residue: Incomplete volatilization of solvents such as NMP will reduce ionic conductivity, and the recycling cost accounts for 15%-20% of the manufacturing cost.

Dry process

Process innovation: Through dry mixing, fiberization, and calendering, uniform combination of active materials and solid-state electrolytes can be achieved without solvents.

Advantages:

Interface optimization: The fiberized binder (such as PTFE) forms a nano-scale conductive network, the contact coverage rate of the active material and the electrolyte reaches 67.2%, and the ion transport efficiency is increased by 3 times;

Cost reduction: Eliminating solvent recovery and drying processes, energy consumption is reduced by 38%-40%, and the overall cost is reduced by 15%-20%;

Material compatibility: Especially suitable for sulfide electrolytes, avoiding solvent reactions to generate by-products, inhibiting interfacial expansion and impedance increase.

A detailed comparative analysis of wet and dry processes is available in the previous article. Click the link to read. 👉 Understanding at a Glance | From Laboratory to Production Line: Analysis of Dry/Wet Slurry Preparation Processes for Electrodes

Dry process accurately addresses two major solid-state challenges

01

Coating crack terminator: Fiberized interface reconstruction

The dry process fiberization equipment uses shear force to form nano-fibers with an aspect ratio > 50 of the PTFE binder, which wraps around the active particles to form a self-supporting network, the interface contact coverage rate reaches 67.2%, and the ion transport efficiency is increased by 3 times;

Multi-roller double-sided calendering technology improves the uniformity of electrode thickness to ±1μm, and the area density deviation is ≤1.5%, eliminating stress concentration from the source;

Zero solvent residue: Liquid-free manufacturing revolution

02

Eliminating the entire process of solvent mixing, coating, and drying, directly dry mixing - calendering and film forming, energy consumption is reduced by 40%, and carbon emissions are reduced by 60%

After Tesla adopted the dry process for its 4680 battery, the cost of a single battery cell dropped from $22 to $12, and "zero-solvent" production was achieved.

Wuhan Chaodian's dry process solution

Wuhan Chaodian's experimental dry electrode film forming machine includes four core processes in the full-process dry electrode technology:

Technical adaptation scenarios

Colleges/Research Institutes : Used for the development of solid-state battery electrode materials (such as three-dimensional carbon nano-cage electrodes, sulfide electrolyte composite electrodes), supporting small-scale tests (roller width 200mm) for rapid process optimization.

R&D departments of new energy enterprises : Pilot stage (roller width 800mm) to verify the feasibility of the dry process, connecting mass production lines, and achieving a smooth transition from laboratory technology to industrialization.

Special scenario needs : Adaptable to flexible solid-state batteries (such as wearable devices), wide-temperature-range energy storage batteries (-40℃~70℃), etc., optimizing electrode performance in extreme environments through precise temperature control (±1℃).

If you need to obtain a landing solution for dry electrode of solid-state battery, please scan the code to register and communicate with Wuhan Chaodian engineers for one-on-one guidance.

Hotline: 027-8580 9599

Chaodian Conclusion

The innovation of solid-state battery electrode manufacturing technology is essentially the synergistic evolution of materials, equipment, and processes. Dry technology provides a feasible path for solid-state batteries to break through industrialization bottlenecks through solvent-free, fiberized interface optimization, and efficient film formation. As leading companies complete the technological verification from the laboratory to the mass production line, solid-state batteries are shifting from "performance advantages" to "cost advantages", and are expected to reshape the power battery competitive landscape before 2030. In the future, the integration of dry processes with atomic layer deposition (ALD), 3D printing, and other technologies may usher in a new era of battery manufacturing.

*Disclaimer*: The views in this article are all from the Internet and are not my own views. Some materials (including pictures) are reproduced from Internet materials and are only for learning and exchange. They do not constitute commercial purposes. The copyright belongs to the original author. Thank you to industry predecessors for their contributions. If there are any disputes regarding the content, copyright, and other issues, please contact us by email for communication and processing cj017@spcmach.com. This platform will verify and reply within 24 hours. This article may not be reproduced without authorization. We will not bear any legal responsibility for any consequences caused by reproduction.

Solid-state battery,All-solid-state battery,Solid-state electrolyte,Dry electrode,Dry battery

Previous Page

Previous Page

Related News

Focus on us