Battery Laboratory Q&A VOL.003: Why do pouch batteries require a secondary sealing process while others do not?

Release time:2025-09-08

Why do pouch batteries

require secondary packaging,

while others do not?

✦

✦

✦

Pouch batteries must undergo secondary packaging. It's really not that we battery equipment suppliers are trying to take advantage of battery companies and R&D engineers. Essentially, it is a "process compromise forced by material characteristics."

The core purpose of secondary packaging is to extract gases generated during the pre-formation stage, seal potential gaps from the primary packaging, and improve the internal vacuum of the cell to ensure tighter adhesion between the electrode and separator. Cylindrical and prismatic batteries do not require this operation due to their rigid outer shells.

The "outer layer" of pouch batteries—the aluminum-plastic film—has an inner CPP heat-sealing layer only 20-30μm thick, roughly the thickness of a human hair.

The top and side seals of the primary packaging are "temporary seals" before electrolyte injection, relying on about 180°C high temperature to melt and bond the CPP layer, but at this point, the cell has not yet undergone formation— During formation, electrolyte decomposition releases trace amounts of CO₂ and H₂ gases, like "blowing air" into the aluminum-plastic film, potentially creating nanometer-scale gaps in the originally tight heat-sealed edges; even more troublesome, residual electrolyte after injection slowly corrodes the CPP layer, reducing sealing strength.

Secondary packaging is not a "redundant step" but a "life-saving patch."

After gas extraction, a second sealing is performed under higher pressure (0.3-0.5MPa) and more precise temperature control (±2°C), re-melting the CPP layer to seal the gaps; some processes also fold and press the edges back, adding a "double insurance" to the aluminum foil gas barrier layer of the aluminum-plastic film.

Laboratory tests show that for the same pouch cell, the water vapor transmission rate after secondary packaging can be reduced to 10⁻⁴ g/(m²・day), two orders of magnitude lower than primary packaging.

This is not because equipment suppliers want to sell more sealing machines; without this step, the cell may bulge and leak after just 300 cycles.

The "confidence" of cylindrical and prismatic batteries comes from their shell materials.

Cylindrical batteries have steel shells thicker than 0.2mm, with the top cover and shell locked by rolling groove and laser welding; the weld seam's airtightness reaches 10⁻⁸ Pa・m³/s, 100 times better than pouch primary packaging.

Prismatic hard cases use aluminum shells with the top cover and shell directly laser welded, with weld depth reaching 80% of the shell thickness, effectively "welding metal molecules into one family." Even if trace gas is produced or internal pressure temporarily rises, the shell will not deform or leak.

When we previously helped a company debug a pouch battery test line, the client thought secondary packaging was time-consuming and skipped it. As a result, 3% of cells showed edge leakage during capacity testing. Upon inspection, the primary packaging edges were softened by electrolyte.

They then added a vacuum secondary packaging machine with temperature precision controlled within ±1.5°C, reducing the defect rate to below 0.1%.

In fact, what equipment suppliers do is "help materials cover their weaknesses," helping companies protect their R&D achievements from being ruined by process defects.

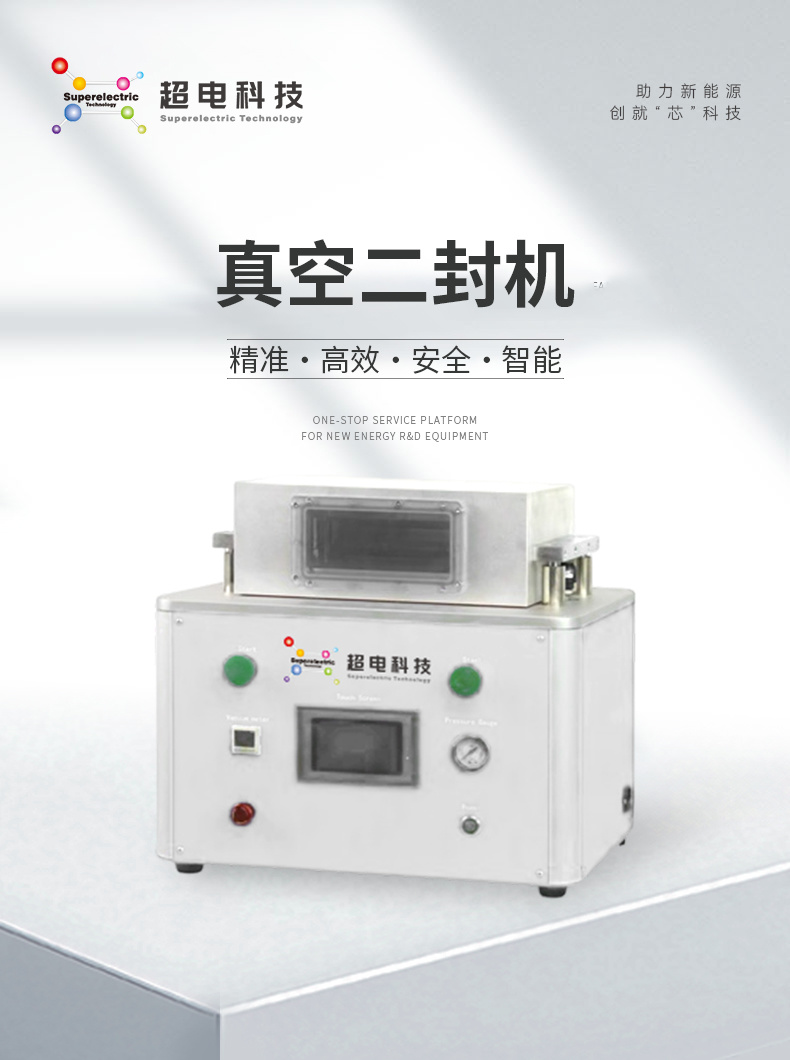

Vacuum Secondary Sealing Machine

Click the image to learn more about the equipment.

Super Battery Technology's vacuum secondary sealing machine is a core device specially developed for the secondary packaging process of pouch lithium batteries and polymer batteries. It integrates automatic puncture venting and secondary vacuum sealing functions, solving issues such as residual bubbles, poor sealing edges, and uneven thickness during pouch battery packaging, ensuring battery safety and long-term cycling stability. It is a key piece of equipment for power and consumer battery production lines.

During R&D testing, using the same aluminum-plastic film, the edge sealing strength deviation with a regular sealing machine for secondary packaging could reach ±5N, while with high-precision equipment, the deviation shrank to ±1.5N.

If you encounter leakage after secondary packaging, it is most likely due to mismatched heat sealing parameters with the CPP layer's melting point or uneven equipment pressure. For more battery R&D process issues, you can consult Super Battery engineers.

Super Battery Technology's resistance tester free sample testing quota event is now open. You can "inspect" resistance and conductivity testers in advance. Powder, electrodes, slurry, and electrolyte can all be tested, and you can get priority scheduling!

Disclaimer: Some content in this article is sourced from the internet. The article does not represent the views of this platform and is for learning and communication purposes only, not for commercial use. If there are issues related to content, copyright, or other disputes, please contact via email at cj017@spcmach.com. This platform will verify and respond within 24 hours. Unauthorized reproduction of this article is prohibited. We do not assume any legal responsibility for any consequences or disputes arising from unauthorized reproduction.

Battery Packaging Process,Secondary Battery Packaging,Soft-pack battery packaging,Battery Secondary Packaging Equipment

Related News

Focus on us