Battery Laboratory Q&A VOL.004: What causes the voltage of assembled lithium-ion button batteries to be abnormally low?

Release time:2025-09-08

@SuperBatteryTech

Battery Lab Q&A vol.004

Common Battery R&D Issues & Solutions

Assembling Lithium-ion Button Cells

Abnormally Low Voltage

What is the cause?

✦

✦

✦

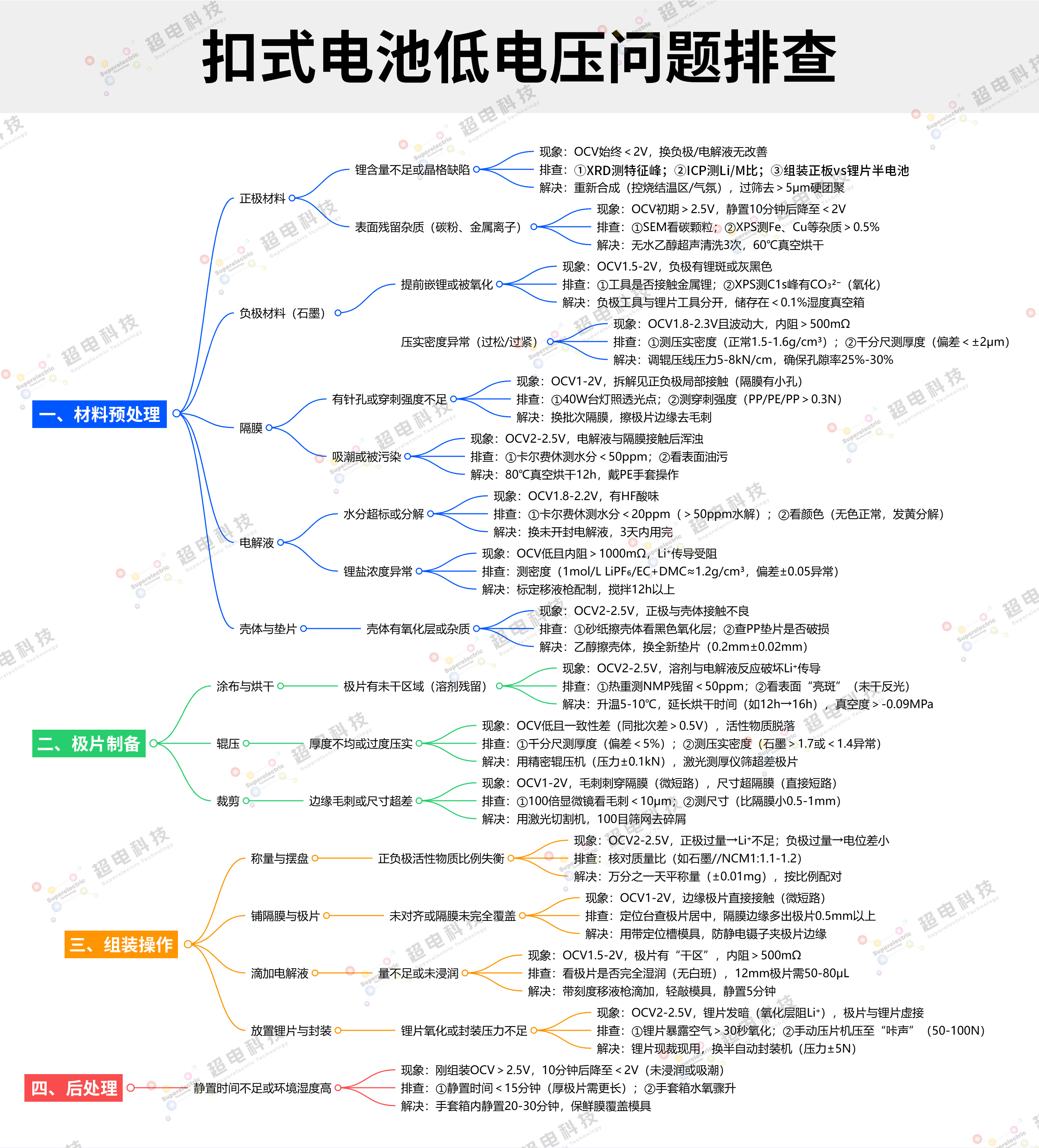

In fact, every step in button cell assembly may hide "invisible pitfalls" that cause low voltage. You can follow the low voltage troubleshooting mind map organized by SuperBatteryTech, breaking down the entire button cell assembly process into four stages: "Material Pre-treatment → Electrode Preparation → Assembly Operation → Post-treatment" to check for abnormal low voltage issues step by step.

Summary of Troubleshooting Process

Check Assembly Operation First Reassemble one cell using a positioning mold to ensure electrode alignment, sufficient electrolyte, and tight sealing. If the voltage recovers, it indicates an operational issue.

Then Check Materials: Replace with known qualified cathode and electrolyte. If voltage is normal, it indicates a problem with the original materials.

Finally Check Electrode Preparation: Compare the thickness, burrs, and solvent residue of new cut electrodes with old ones to identify if rolling or cutting issues exist.

| Button Cell Intelligent Equipment

Click the image to learn more about the equipment

The stability of laboratory button cell R&D equipment can indeed reduce a lot of "repetitive trial and error" — the material formula is correct, coating parameters are right, yet samples and time are wasted due to assembly details.

Wuhan SuperBatteryTech's complete laboratory button cell assembly equipment solution is designed precisely to address these pain points: from material mixing, to button cell sealing machines, to testing cabinets, covering the entire process to reduce human operation errors.

This solution can help you reduce low voltage issues caused by sealing by 80%, improve single experiment sample efficiency by 40%; more importantly, by precisely controlling rolling density, sealing pressure, and other parameters, it stabilizes material performance data and avoids misjudging material potential due to process fluctuations.

Reducing repeated experiments can save 30% of material consumption and debugging time monthly. If you are troubled by "unstable processes slowing down R&D," leave a request in the comments. We can provide customized solutions tailored to your material system to take your experimental efficiency to the next level.

SuperBatteryTech's resistance tester free sample testing quota event is now open. Pre-"inspect" resistance and conductivity testers; powders, electrodes, slurries, and electrolytes can all be tested, and you can get priority scheduling! Scan the QR code below to grab a spot!

Assembly buckle voltage,Assembled battery voltage is low,Power-off Assembly Process,Troubleshooting Low Voltage Issues of Button Cell Batteries

Related News

Focus on us