Battery Laboratory Q&A VOL.005: Which technology produces better cell performance, stacking process or winding process?

Release time:2025-09-09

@Super Battery Technology

Battery Lab Q&A vol.005

Common Issues & Solutions in Battery R&D

Stacking process and winding process,

which technology produces

better cell performance? Better?

✦✦✦

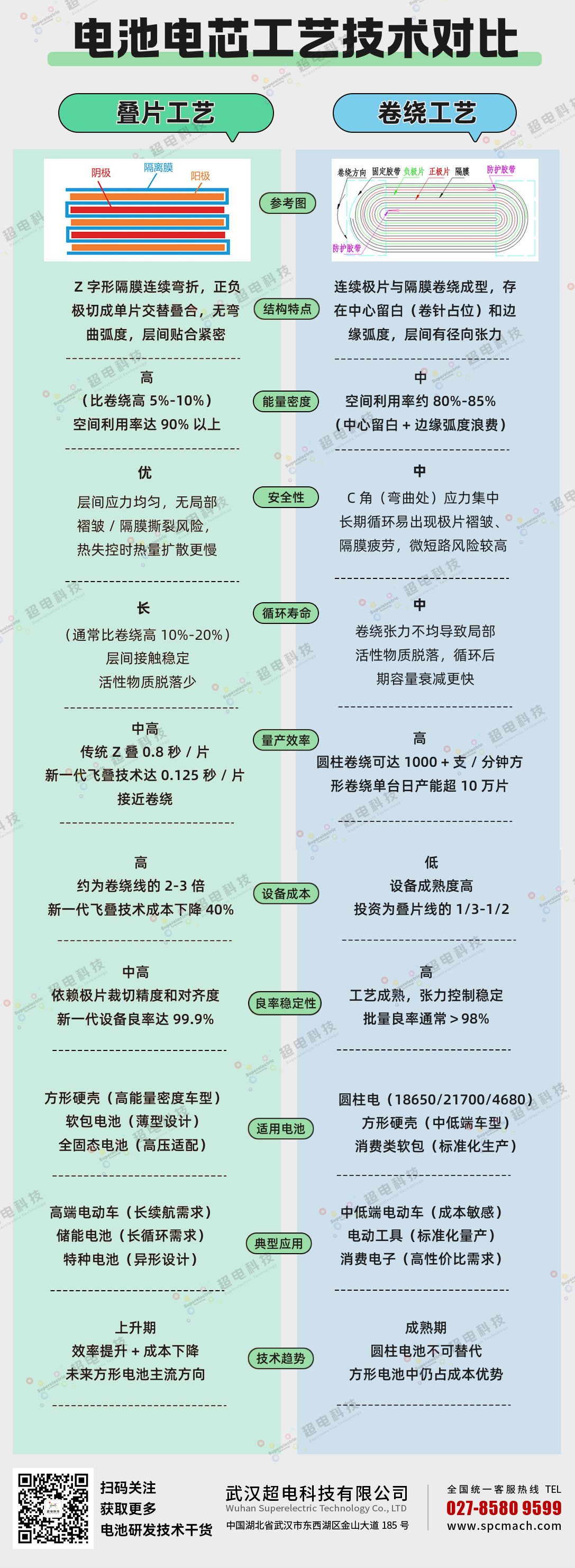

There is no absolute "better" between stacking and winding processes; each has its technical characteristics suited for different battery application scenarios. The core differences lie in structural design, performance, and mass production features.

Winding is an efficient standardized production of "one-roll forming".

Stacking is a precise customized process of "layer-by-layer stacking."

Wuhan Super Battery Technology compares and analyzes the differences between stacking and winding processes from the following dimensions:

Summary:

If pursuing high energy density, long life, and high safety (such as high-end electric vehicles and energy storage), stacking is the better solution;

If focusing on mass production efficiency, cost control, and standardized production (such as mid-to-low-end models and cylindrical batteries), winding has more advantages;

In terms of technological development, stacking is narrowing the efficiency and cost gap through equipment upgrades (such as flying stacking and thermal bonding), and its share in prismatic batteries will continue to increase in the future.

Choosing the process also means choosing the right equipment.

The advantages of stacking and winding processes require matching appropriate equipment scale to be realized.

Wuhan Super Battery Technology's stacking and winding machines are specially designed for laboratories, pilot lines, and small batch production.

The equipment supports flexible debugging, making process parameters more reliable during the R&D phase;

Cost-friendly, requiring no complex infrastructure, plug-and-play production, especially suitable for startups or labs with limited budgets expanding production;

Efficiency adaptation, yield stable above 95%, meeting both the timeliness of R&D sampling and the delivery needs of small batch customized orders.

If you are currently in the "process validation" or "small batch production" stage, Wuhan Super Battery Technology's stacking/winding machines are the optimal solution balancing "precision, efficiency, and cost."

Super Battery Technology's resistance tester free sample testing quota event is now open. Pre-inspect resistance and conductivity testers; powders, electrodes, slurries, and electrolytes can all be tested, and priority scheduling is available! Scan the QR code below to grab a spot!

Disclaimer: Some content in this article is sourced from the internet. The article does not represent the views of this platform and is for learning and communication purposes only, not for commercial use. For issues involving content, copyright, or other disputes, please contact cj017@spcmach.com. The platform will verify and respond within 24 hours. Unauthorized reproduction of this article is prohibited. We assume no legal responsibility for any consequences or disputes arising from unauthorized reproduction.

Lamination Process,Winding Process,Lithium Battery Winding Equipment,Battery stacking equipment

Related News

Focus on us